Production and filling plan for asthma aerosol

Production process of topical skin spray

The commonly used solvents for the preparation of topical skin sprays are ethanol and water. However, due to the different nature of the active ingredients of drugs, specific pharmaceutical solvents and other additives must be selected to prepare solution type sprays, lotion type sprays or suspension type sprays. Appropriate excipients can make the drugs play a good role.

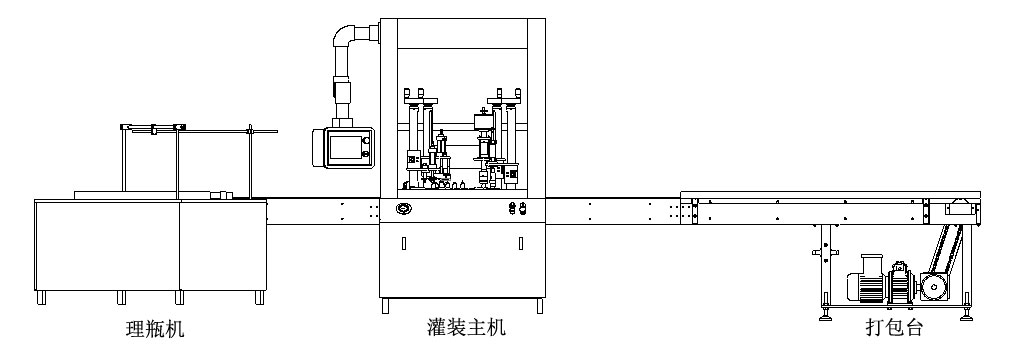

If the spray without propellant gas is made, it is composed of a manual pump (or valve system) and a bottle body. The valve system can be a quantitative valve system or a non quantitative valve system. The basic composition of the valve system is the basic pump, screw cap, immersion tube, washer, push button, spray head, integrated atomizer and protective cover. The process flow is: raw material production - bottle sorting - filling - valve installation - cap rolling - labeling - coding - packaging.

If it is made into an aerosol containing a propellant, it consists of an aerosol can (iron or aluminum can), a valve, propellant gas, a nozzle, an outer cover, etc. A valve is a set of valves consisting of a valve cup, a valve chamber, a valve stem, an inner gasket, an outer gasket, a spring, and a suction tube and button. Commonly used propellant gases include liquefied petroleum gas (propane, butane), dimethyl ether, nitrogen, carbon dioxide, Freon, tetrafluoroethane, etc. Choose the appropriate propellant gas based on the characteristics of the product. The process flow is as follows: raw material production - bottle sorting - liquid filling - valve installation - sealing - filling with propellant gas - weighing - water inspection - nozzle fastening - outer cover fastening - packaging, etc.

Cold filling method: Freeze the propellant and directly fill it into a container containing the medicine, then immediately install the valve and tighten it. This method requires refrigeration equipment and low-temperature operation, resulting in significant loss of propellant, so its application is limited.